Conventional Well point Dewatering

Well point dewatering is one of the most efficient, adaptable and consistent methods of ground water control available. We supply the complete groundwater control service: from site survey design and calculations (using our extensive knowledge of existing subsoil conditions), to recommending and installing the best possible ground water dewatering system. As part of our installation, we install a number of well point spear tubes of 50mm diameter, screened by filter packed gravel, so the underground water is drawn down efficiently.

As standard, all our well pointing dewatering pumps are fitted with high capacity vacuum pumps, allowing the maximum draw-down and highest number of well points to be installed per pump. Our self-priming diesel powered dewatering pumps which are high efficiency pumps are equipped with Vacuum Kits at the suction side of the dewatering pumps are ideal as they are fully automatic self-priming type pumps powered by either diesel or electric motors.

The well point installation is one of the most conventional methods of dewatering and has not much changed conceptually in years from the time of its inception. The basic components are a self-priming diesel powered pump, well point spears and swing hose which is connected to header ring main pipes.

The intake end of the Sky dewatering pump set is connected to a level header manifold, which runs alongside the perimeter of the proposed excavation.

The header pipe distributes vacuum to a series of individual well points and transfers the water lifted from these well points to the dewatering pump set. Well points are long thin tubes constructed with a screen intake and usually a surrounded by a filter pack gravel, drawing the water from the ground by the suction generated by the pump. The aforementioned well points are generally small in diameter mainly of 50mm sizes.

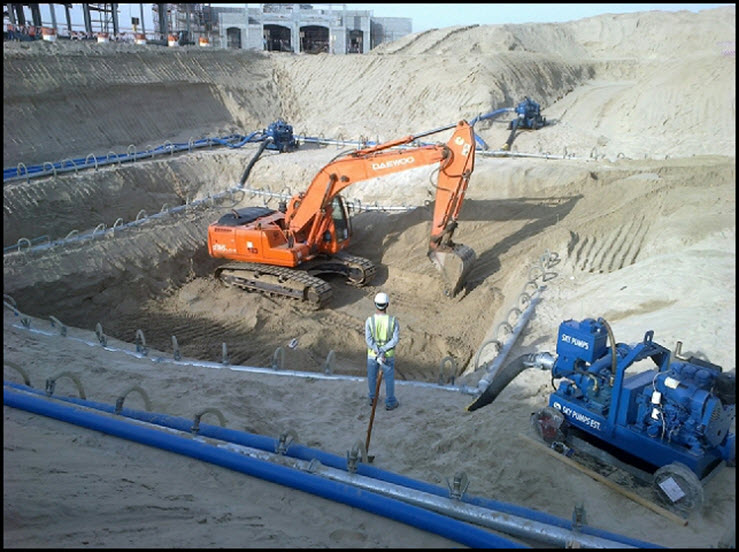

Well point dewatering systems enable the groundwater table to be lowered for deep and large construction sites in high permeable soils. It is a proven and very flexible system within this environment. The water is pumped from well points, installed along the perimeter of the site. The well points are jetted in and spaced to obtain the optimal draw-down against lowest capacity. The well points with integral strainers are then joined to transparent swing flexible hoses, which are connected by quick release couplers to the ring main header pipe. The ring main header pipes are then connected to the self-priming or vacuum assisted centrifugal pumps.

A well point dewatering system can consist of well points with 1metre centre distance and are in hundreds of numbers depending upon the construction area and the required installation. These well point network is connected in series with the Sky high vacuum priming diesel dewatering pumps. This is a popular solution within the construction and dewatering industry. Typically, well points are installed around the perimeter of an excavation or within the excavation if there are space constraints and later be sacrificed as the abandon dewatering system which is installed below the formation level thereby facilitating construction and also maintaining the lower ground water levels for the required duration of the project.

Closed Loop Well Point Dewatering Installation

With deeper excavation above 5metres below ground level and going upto 9 metres in a sub saturated strata, a multi-stage well pointing dewatering installation would be proposed and installed to achieve the required excavationdepth.

Trench Excavation with Well Point Dewatering Installation

Depending upon the width of the trench and the radius of influence of the installed system single side or twin side installation of the well points would be adapted to achieve the required depths. This method is adapted for pipelines and other similar applications with progress in installation the system installed is rolled over alongside the route, preceding excavation and pipe laying. Equipment from a previously completed and backfilled section is installed at the head of the line, removing the need for large quantities of equipment.

Well pointing systems are used principally to lower groundwater levels around foundations ensuring stable working conditions are maintained. A closely spaced series of small-diameter shallow tubes (or wells) are connected to a common header pipe where a partial-vacuum is created. A typical installation of the Sky high-efficiency vacuum dewatering pump can control a 100m length of well points. For draw-downs greater than 6m, further stages of well points are often installed at lower levels as the excavation progresses.

Well pointing is particularly effective for moderate draw-down duties across a wide range of ground types from gravel through to fine sand as often found in the Middle East. Drilling installation may be required in coarse or hard soils but for much of the Middle East in sandy environments a more rapid and cost-effective well point installation process is to jet in the well points using high-pressure water jetting pump.

In addition to a more rapid a lower cost installation, pre high pressure jet flushes the well point locations also encourages an improved hydraulic conductivity through the granular filter pack to enhance performance iof the entire system in varied heterogeneous soils structures.